which of the following is a type of machine safeguarding osha 10

Which of the following is a type of machine safeguarding osha 10 Thursday May 19 2022 Any machine part function or process that may cause injury must be safeguarded. These injuries can be prevented with the proper use of machine guards.

Machine Guarding Safety Instructions Youtube

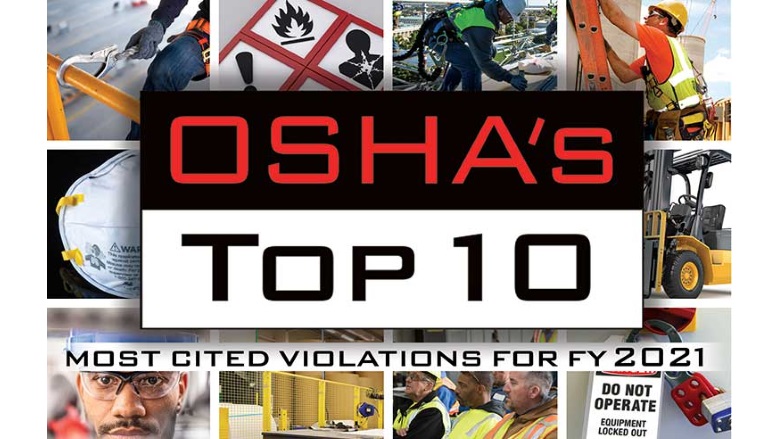

Power transmission device The power transmission apparatus is all components of the mechanical system which transmit energy to the part of the machine performing the work.

. Hazardous Mechanical Motions and Actions. Device that uses cable attached to hands which allows access to the point of operation when the slideram is up and automatically withdraws hands when the slideram begins to descend. Rotating Motion In-Running Nip Point Reciprocating Motion Transverse Motion Cutting Action Punching Action Shearing Action.

The most common types of machine guards are. Machine safeguarding helps protect workers from preventable injuries in all three areas. Any type of machine operation injury can be.

OSHA Quiz 8 Machine Guarding. Which of the following is a type of machine safeguarding osha 10 Sunday May 8 2022 If a new guard causes interference 4. Safeguarding as described by OSHA in 1910 Subpart O Machinery and machine guarding.

Which of the following is a type of machine safeguarding punching. These can include the movement of rotating members reciprocating arms and cutting teeth. There seem to be as many hazards created by moving machine parts as there are types.

There are several mechanical motions that pose risks to workers. What are the 2 types of primary safeguarding methods. The point of operation from where all the work is performed.

Primary methods Guards Devices. Of power transmission apparatus less than 7 feet from the floor or working platform must be guarded. The type of operation size or shape of stock method of handling physical layout of the work area type of material and production requirements or limitations will help to determine the.

The Occupational Safety and Health Administrations OSHAs requirements for machine guarding are found in 29 Code of Federal. OSHAcademy Course Course 154 Machine Safeguarding. Machine Guarding OSHA 10-Hour Outreach Training General Industry.

This problem has been solved. Power transmission apparatus which feeds energy to machines. In terms of controlling amputation hazards employees are protected from hazardous machine work activities either by.

Type A and B Gates are both recognized methods for power press safeguarding. Which of the following is a type of machine safeguarding. Any machine part function or process which may cause injury must be machine guarded.

To the basic concepts and principles for machine safeguarding as described by OSHA in 1910 Subpart O Machinery and machine guarding. Machine guards are essential for protecting workers from needless and preventable injuries. 29 CFR 1910212 a 1 states that one or more methods of machine guarding must be used to protect operators and other employees from hazards including those created by point of operation in-running nip points rotating parts flying chips and sparks.

Which of the following is a type of machine safeguarding. A wide variety of mechanical motions and actions may present hazards to the worker. The most common types of machine guards are.

All machines consist of three fundamental areas the point of operation the power transmission device and the operating controls. Machine Guarding OSHA 10-Hour Outreach Training General Industry. A Pullback devices b Safety trip controls c Electro-mechanical sensing device d Two-hand control.

1 effective machine safeguarding or 2 lockouttagout where safeguards are rendered ineffective or do not protect employees from hazardous energy during servicing and maintenance operations. A True b False. Machine guarding is basically guarding or protecting machine parts that are the most dangerous.

There are many ways to design and use machine safeguarding. There seem to be as many hazards created by moving machine parts as there are types of machines. The following are all machine safeguarding requirements except.

Presence sensing safety trip controls two hand control pull back restraint. OSHA states that mechanical hazards are most likely to occur in three major areas. Calculating Safe Mounting Distances For Safeguards Ehs Today.

A good rule to remember is. Any part of a machine which ___ while in operation can cause a hazard. Moving parts which are part of the machine or bigger system.

There are four main types of machine guards. The purpose of machine guarding is to protect the machine operator and other employees in the work area from hazards created during the. Understanding the different types of mechanical motions is the first step towards protecting your workers from potential harm from the danger zones caused by them.

Which of the following is an example of a safeguarding device. Simply so what are the most common types of machine guarding. The Occupational Safety and Health Administrations OSHAs requirements for machine guarding are found in 29 Code of Federal.

Must prevent workers from lubricating a machine without removing the safeguard. Any part of a machine which ___ while in operation can cause a hazard. Eight Basic Types of Hazardous Mechanical Motions and Actions.

The operator initiates the machine cycle. The average total cost to a business for a workplace amputation is estimated at 133000 111000 for a crush injury and 95000 for a fracture. Some are even killed.

Safeguards Guards Devices Point of operation The point of operation is where work is performed on the material such as cutting shaping boring or forming of stock. _____ True or False. What is machine safety.

2 Fixed limited access guards. Types of Safeguarding. The injured employee also incurs time away from work.

Machine Guarding Named To Osha S Top Ten Violations List For 2021 The National Provisioner. Feeding and ejection methods is a type of machine safeguarding. Machine Guarding Best Practices Occupational Health Safety Commonly Used Machine Guards 12 Table 2.

Commonly Used Machine Guards 12 Table 2. Which types of moving parts need guarding. Types of Machine Safeguards Safeguarding machinery.

This problem has been solved. 1 Assigns responsibilities to those affected and outlines evacuation routes. Machine safeguarding helps protect workers from preventable injuries in all three areas.

How many main types of machine guards are there. The shafting flywheels pulleys belts chain drives etc.

Machine Guarding 101 The Basics Kha Online Sds Management

Machine Guard Safety Training Video Course Safetyinfo Com Youtube

Osha 2045 Machinery And Machine Guarding Standards Chesapeake Region Safety Council

Machine Guards Eliminate Hazards For Employees Article The United States Army

2021 Top 10 Osha Violations Machine Guarding 2022 01 25 Ishn

Machine Guarding Named To Osha S Top Ten Violations List For 2021 The National Provisioner

Machine Guarding Approach Management Services

Osha Standards For Industrial Companies Industrial Safety Osha Safety Training Health And Safety Poster

Crane Balancing Act Truck Cranes Crane Construction

Williams 12 X 3 4 Drive Impact Extension 6 113 In 2022 Schuylkill County Driving Valley View

Kpa Osha Machine Guard Requirement Compliance Checklist

What Is Machine Safeguarding T P Supply Co

Top Questions When Selecting Machine Guarding Wirecrafters Blog